News

30 Sep 2019

Here today… and tomorrow… and the next day

Subscribe to CX E-News

INSTALLATION

by John O’Brien.

Shows and live productions are pretty transitory affairs. Huge efforts go into the logistics and budgeting for just one show and then, save for a few faded flyers and fanboy clips on the internet, the next day it’s all but a memory. Permanent installations are just that – permanent. They will be there the day after they’re finished and, until they fall apart or are upgraded, will be an enduring testament to your prowess (or lack thereof!).

Making the transition

I’ve written plenty about transferable skills and there are heaps of parallels with gigs and installs. The key is using your show expertise while learning a whole new bag of tricks. You’ll will still run cables, connect them to equipment, then test it and use it. But so many other factors differ.

For starters, cable types and connectors might diverge from what you are familiar with, particularly their attachment method. A mainstay of temporary production, gaffer tape, is rarely seen on a building site. Here it is swapped for cable ties, clips and any manner of proprietary tie-downs.

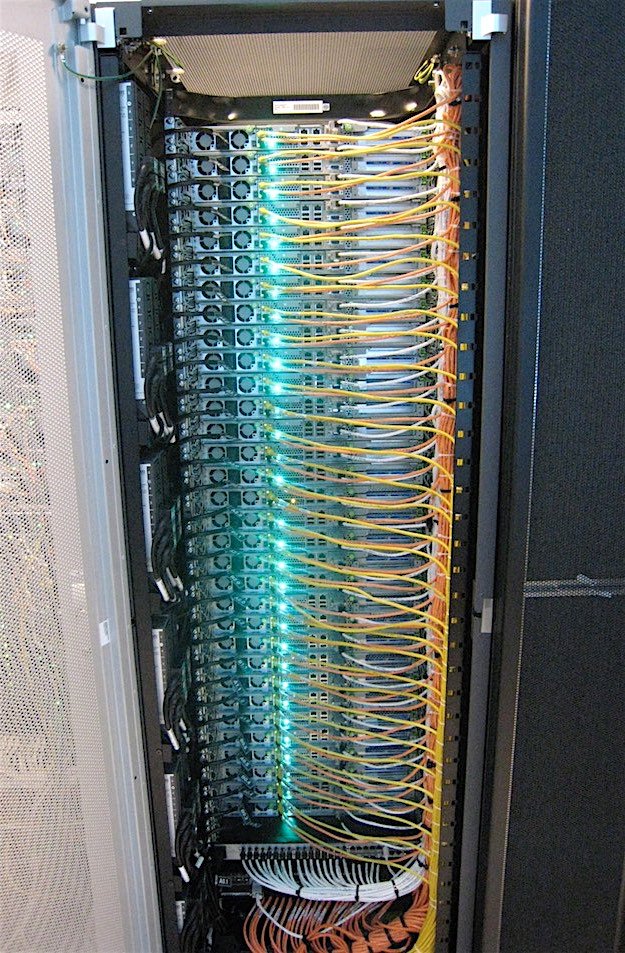

Copper is copper but different cable stranding, shrouding and sheathing applies to different uses. The most obvious is solid core CAT cabling for all in-wall applications but stranded for fly leads. Same with power cabling. I loved getting all OCD on “tram-tracking” cables across gig access ways but that level of neatness applies to all install wiring and fixings.

Let’s not even get into rack layout and building – an artform unto itself.

Even the connectors can get weird. Live, analogue audio using XLR is defacto; install, you can end up with terminal mounts, screw downs, punch blocks, Phoenix, RCA or even banana plugs to transfer the same signal.

8 ohm or 100v? Which one comes down to system design and specification. Depending on where you are in the food chain, you may or may not get a say in that.

Building in a new industry

The construction industry is far bigger and more entrenched than the AV production industry. With that comes established conventions for all manner of things, from site hierarchy to shop stewards.

The most obvious difference is working hours – daylight basically – which is a rude shock for a gig vampire. More subtle are the power plays that establish who gets what treatment (and payment) on site. On the bigger and more unionised sites there are usually better awards and better conditions for those on the tools but more hoops to jump through from a management perspective.

Keeping Site Managers and Project Managers onside really helps your cause.

Schedules, tickets and compliance are relatively easy to achieve – just tick the boxes. Hopefully, the boss allows enough time for that. If not, you’re up against a mountain. The primary problem I’ve seen is AV contractors being a bit of an add-on to the main program.

Commercially, AV sub-contractors are becoming part of the electrical contract. This has the distinct benefit on the head builder’s program. Domestically, AV integrators are often engaged directly by the end client. The main building contractor and electrical sub-contractors might not see your work (or even presence) as a priority. After all, they get no direct financial benefit from assisting you.

This will evolve as builders and other trades see ever more white vans full of black boxes … as will security measures ensuring that said boxes don’t mysteriously disappear.

Hitting your cues

Timing is another big adjustment. The construction industry is by nature slower and more deliberate than gig world. There is a long, drawn out design and approvals phase before tenders, RFIs and contracts go out. You’ll next have to wait for the basics of site work, concreting, framing and roofing before even getting near site.

The first hands-on AV involvement is pre-cabling, which requires licensed cablers or electrical contractors. Then you wait for other trades to do their thing before first fit happens. Here, you’ll prep cabling in rack areas, maybe get some screen brackets and wall plates in. Then back to the factory to finish off the racks and test the gear (your schedule has allowed this, right?) while the painters and decorators do their thing.

Finally, when it comes to the pointy end of the game, you get to do the final fit and commission the system. The job is likely already over budget, invariably over schedule and the end client wants it all NOW (“but can I just change a couple of things?”). And that’s when the gig training really kicks in.

Your ever-decreasing time window is under great pressure when all of the main players are starting to get frazzled and your gear isn’t working flawlessly straight out of the box. Cool, calm but firm wins the day.

Being next to last on the schedule, you will not have much wiggle room if things go wrong or if the pre-wire didn’t include those essential runs that are now covered by expensive final finishes.

Good, clear communications with the main builder and electrical contractor from early in the project are paramount to your success.

Manual labour in the office

On a smaller domestic or simple boardroom fitout, you won’t have to do much more than supply, install and commission the gear. A quick once-over with the end client and you are ready to send an invoice. But the bigger the site, the bigger the contract, the bigger the risk.

Larger jobs, and particularly consultant specified ones, tend to require greater amounts of paperwork – boring, but paying attention to this means you get paid too. Progress reports, progress payments, transmittals and variations – all part of general contract administration.

When you think it’s all done, handover documentation may include: site manual, user manuals per room, assets register, product manuals for each and every product supplied, maintenance schedules and training arrangements.

After the defect rectification period, you will still be responsible for a site warranty and enabling manufacturer warranties as required. The beauty of all of this is getting long term maintenance contracts. If you play that well, there will likely be regular upgrades over time too. All dollars in the bank for your installation company.

The ultimate installation

Emptying my bank, I embarked on the ultimate installation a few years ago – building my own house from scratch. Wearing my best Project Manager’s hat, I had GANTT charts and spreadsheets galore, outlining a tight but achievable schedule of 18 months.

Six months in, a prolapsed disc smashed any hope of meeting that timeline! Fortunately, I recovered enough to get back on the tools nine months later but it still took a further 4 ½ years to complete. I blew the budget too but we do now live with the rewards of a meticulously built home!

For ease of maintenance it’s purposely low tech but I did pre-wire for four audio and two video zones. One day I might even finish the custom patch panel to hook it all up! Making and installing ELV light switches with stainless sheet and aircraft style toggle switches was a highlight.

Skills gained from construction sites were sure handy but the gig skills of perseverance, lateral problem solving and getting the show on before inspector time were of equal importance.

Everlasting impressions

It’s kind of warming to go back and visit some of the installations that you are most proud of. What a good feeling to know that you have left a mark that is a little more permanent than a used gaffer ball in the rubbish bin?

CX Magazine – Sept 2019 Entertainment technology news and issues for Australia and New Zealand – in print and free online www.cxnetwork.com.au

© CX Media

Lead image: “P1000909.JPG”by benketaro is licensed under CC BY 2.0

Subscribe

Published monthly since 1991, our famous AV industry magazine is free for download or pay for print. Subscribers also receive CX News, our free weekly email with the latest industry news and jobs.